Latest

Featured

Ceramic Bisque Bunny Gnome

MB1598 Bunny Gnome in ready to paint, cone 04 Low-Fire Ceramic Bisque

4 L x 5.5 W x 9.75 H

Ceramic Bisque Large Mushroom Lantern

MB1644 - Large Mushroom Lantern in Ceramic Cone 04 Bisque

7 L x 7 W x 9.5 H

This item is unpainted.

You are purchasing an unfinished, Ready to Paint, Piece of Ceramic Pottery

Speedball Bose Base Blue

Speedball

Boss Base

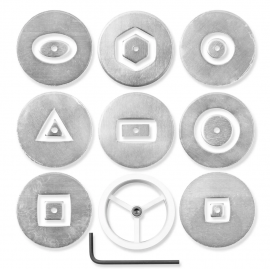

The Speedball Boss Base, developed in

partnership with professional potter, Rich Brown, and inspired by tools and

traditions of North Carolina production potters, this amazing tool allows for

the ultimate ergonomic experience while delivering unmatched consistency and

ease. Adding efficiency and precise results to any studio setting, the Boss

Base will become your tool of choice to easily open your small cups, mugs or

plates while ensuring a uniform bottom to every piece. Available in six vibrant

colors (Red, Blue, Orange, Green, Pink, Purple); 3/8" size.

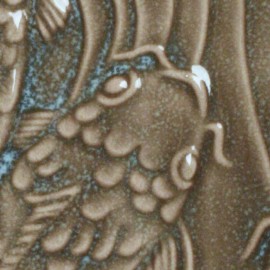

Louisiana Bayou Floating Glaze by Spectrum

1451 Louisiana Bayou Floating Glaze by Spectrum

16-ounce container

AP, non-toxic, Dinnerware Safe

.jpg)

The Cone 4/6 Floating Glazes are all lead-free and dinnerware safe.

They require 2-3 coats for full coverage.

Samples are at Cone 5 and changes in temperature can produce variations on the

appearance

Edger Rib 1 Large (Red)

Edger Ribs

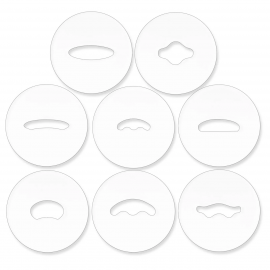

Xiem Edger Rib 1 Large (Red) is made of high-quality

anodized aircraft aluminum. Our Edger

Ribs provides a simple solution for creating quick footing designs and decorating

textured surfaces to your thrown pottery.

With Edger Ribs, enhancing your pottery surface with a

creative touch has never been easier.

These ribs are made of anodized aluminum, ensuring long-lasting use and

rust resistance.

They come in four unique styles with each featuring three precision

edging patterns and in three different sizes (small, medium, and large) to

select from.

-270x270.jpg)

-270x270.jpg)

-270x270.jpg)

-270x270.jpg)

-270x270.jpg)

-270x270.jpg)

-270x270.jpg)

-270x270.png)

-270x270.png)

-270x270.png)

-270x270.png)

-270x270.jpg)

.jpg)

.jpg)